In the realm of power electronics, IGBT modules stand out as indispensable components that play a key role in enabling efficient and controlled power flow. These modules combine the advantages of high input impedance of a MOSFET and low on-state power drop of a bipolar transistor, making them a versatile choice for a range of applications. From renewable energy systems to industrial motor drives, IGBT modules are utilized to manage and deliver power with precision and reliability.

With the ability to handle high power levels while offering fast switching speeds, IGBT modules have become the go-to solution for enhancing system performance and energy efficiency. Their construction typically consists of multiple IGBTs and diodes in a single package, providing a compact and integrated solution for power conversion needs. As industries continue to evolve towards more electrified solutions, understanding the fundamentals and applications of IGBT modules becomes increasingly vital for engineers and designers alike.

Benefits of IGBT Modules

IGBT modules offer enhanced efficiency, allowing for optimal power utilization in various applications. With their low conduction and switching losses, these modules contribute to energy savings and reduced operating costs. Their high thermal stability ensures reliable performance even in demanding conditions.

The compact design of IGBT modules makes them space-efficient, ideal for modern electronic devices and power systems where size constraints are a concern. This feature enables streamlined integration and layout flexibility, enhancing system design and overall efficiency.

Additionally, IGBT modules provide robust protection features, such as overcurrent and overvoltage protection, safeguarding the connected equipment from potential damage. This ensures operational safety and longevity, making IGBT modules a reliable choice for critical applications.

Application Areas

IGBT modules find widespread applications in various industries due to their high efficiency and reliability. In the power sector, these modules are commonly used in renewable energy systems such as wind turbines and solar inverters. Their ability to handle high voltages and currents make them essential components in power generation and distribution.

In the automotive industry, IGBT modules are utilized in electric vehicles and hybrid cars for controlling the flow of power between the battery pack and the drivetrain. This enables efficient energy management and contributes to the overall performance and sustainability of electric vehicles. By enabling precise control over power flow, IGBT modules play a crucial role in optimizing vehicle efficiency.

Another key application area for IGBT modules is in industrial machinery and automation. These modules are integrated into motor drives, frequency converters, and welding equipment to regulate voltage and current levels, ensuring smooth operation and improved energy efficiency. The reliability and ruggedness of IGBT modules make them ideal for demanding industrial environments where precision and consistency are paramount.

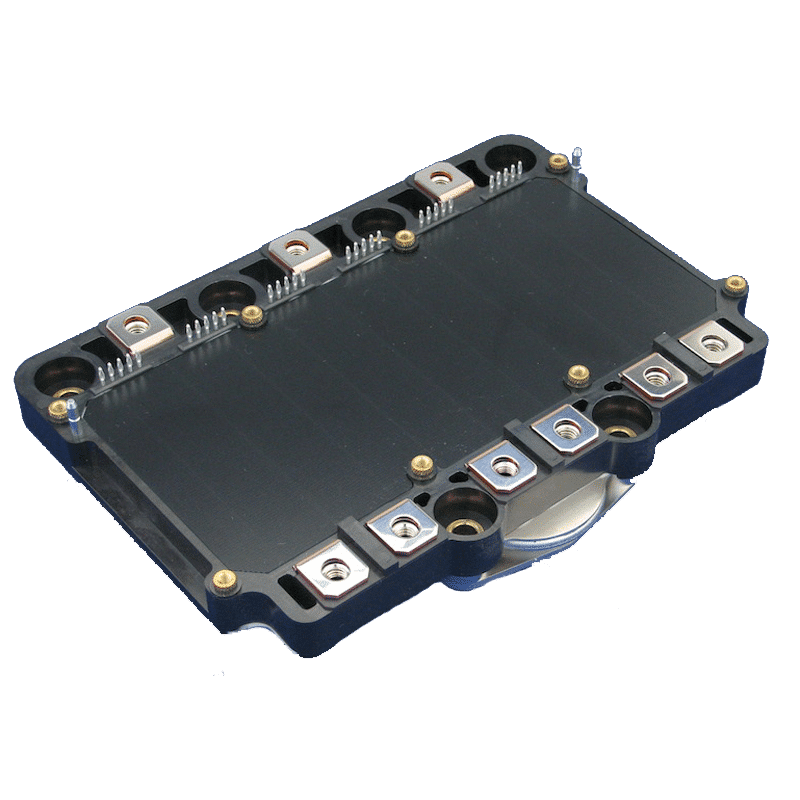

IGBT Module

Future Developments

In the realm of IGBT modules, ongoing research and innovation continue to drive advancements in efficiency and performance. One key area of focus for future developments is the enhancement of thermal management systems to further optimize power dissipation and ensure reliable operation even in demanding conditions.

Additionally, researchers are exploring ways to reduce the overall size and weight of IGBT modules without compromising their power capabilities. This could open up new possibilities for the integration of these modules in various applications, ultimately expanding their reach and impact in different industries.

Looking ahead, developments in materials science and manufacturing techniques are poised to revolutionize IGBT modules, paving the way for even higher power densities, improved switching speeds, and enhanced ruggedness. These advancements hold the potential to unlock new horizons in power electronics and shape the future of energy-efficient technologies.