Actuated valves and controls play a crucial role in enhancing industrial efficiency across various sectors. Established in 1991, Valworx has solidified its position as a leading supplier of these essential components with a focus on quality and reliability. With ISO 9001 certification, Valworx is committed to providing top-notch automated valve assemblies to meet the diverse needs of industrial, institutional, and government markets. Offering a wide range of products, they ensure quick turnaround times by building, testing, and shipping same day, underscoring their dedication to customer satisfaction and operational excellence.

Benefits of Actuated Valves

Actuated valves offer precise control and automation, leading to increased operational efficiency. With actuated valves, adjustments can be made remotely, reducing the need for manual intervention and streamlining processes. This translates to improved productivity and cost savings for industrial operations.

Another key benefit of actuated valves is their reliability and consistency in performance. By relying on automated controls, potential human errors can be minimized, ensuring a more reliable operation. This level of consistency is crucial in maintaining optimal production levels and preventing costly downtime due to malfunctions.

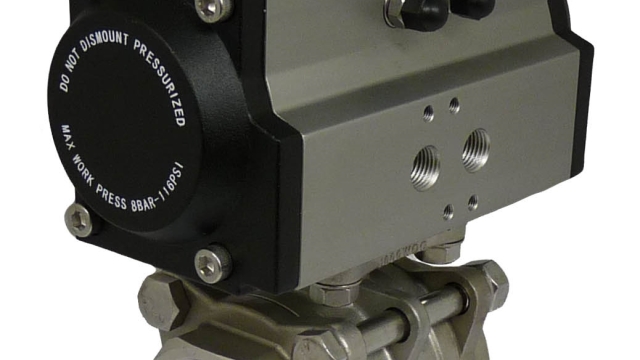

Actuated valves and controls

Actuated valves also contribute to enhanced safety in industrial environments. With automated systems in place, operators can monitor and control valve functions from a safe distance, reducing exposure to potential hazards. This increased safety factor not only protects personnel but also safeguards equipment and the overall integrity of the operation.

Applications of Actuated Valves

Actuated valves play a crucial role in a wide range of industrial processes, offering precise control over the flow and direction of various types of fluids. These valves are commonly used in the oil and gas industry, where they help regulate the flow of crude oil, natural gas, and other petroleum products through pipelines and storage tanks.

In the manufacturing sector, actuated valves are utilized in automated production lines to manage the flow of different materials such as chemicals, gases, and liquids. By integrating these valves into the production process, manufacturers can ensure efficient operations, improve product quality, and enhance overall productivity.

Actuated valves are also essential in the water and wastewater treatment industry, where they are employed to control the flow of water, chemicals, and other substances in treatment plants. These valves enable operators to optimize the treatment processes, monitor water quality, and comply with environmental regulations to safeguard public health and the environment.

Quality Assurance at Valworx

At Valworx, quality assurance is a top priority in our processes. We take great care to ensure that each actuated valve and control system meets the highest standards of quality and reliability. Our ISO 9001 certification is a testament to our commitment to delivering products that perform optimally in industrial, institutional, and government settings.

We have a rigorous testing protocol in place to guarantee the functionality and efficiency of our automated valve assemblies. Each system undergoes meticulous testing procedures before being shipped out to our valued customers. This meticulous attention to detail helps to ensure that our products consistently meet or exceed industry standards, providing peace of mind to our clients.

Our dedication to quality assurance extends beyond the manufacturing process. We also prioritize ongoing customer support and service to address any concerns or issues that may arise post-purchase. Our team is always ready to assist our customers with any technical questions or maintenance needs, reinforcing our commitment to both quality products and quality service.